Beam

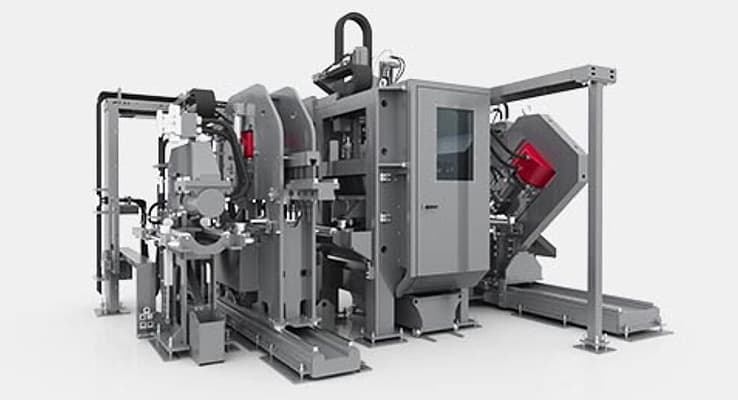

An Automated Structural Steel Beam Welding System can be described as a robotic welding machine that is specifically designed for structural steel fabricators. It offers a compact footprint, complete robotic automation, and integration with specialized software. The robotic welding solution can be applied to any size fabrication shop.